Stock lumber is almost never the size it claims to be.

For instance, wooden flat frames are typically built of either 1x3 or 1x4. Those numbers are supposed to be the cross sectional measure of the board. However, the actual true measure of a 1x3 is 3/4"x2 1/2". It used to be 3/4"x2 3/4". The actual measure of a 1x4 is 3/4"x3 1/2".

Similarly, actual measure of a 2x4 is 1 1/2"x3 1/2", and a 2x6 is 1 1/2"x5 1/2".

The nominal dimensions are meant to express the rough cut measurement of the lumber before it is planed to a smooth finish.

The main thing to remember is that when you are cutting parts you must make sure that you deduct the actual rather than the nominal size of the lumber you are using.

-------------The standard theatrical unit has long been the flat. This is an open frame covered with a lightweight material. Traditionally, frames were wood and were covered with painted fabric to represent walls. More recently, frames have been made of metal tubing and coverings have been thin plywood.

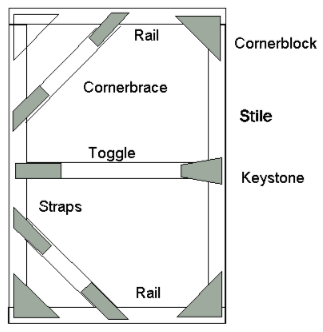

The standard flat, also referred to as a "theatre" or "Broadway" flat, is a wooden framework made of 1x3 or 1x4 pine. The frame pieces are layed flat to the surface of the unit, and assembled using butt joints held together with cornerblocks and keystones (pre-cut 1/4 ply gussets). The covering is canvas or muslin, glues to the frame.

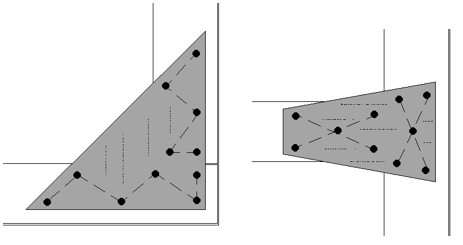

Corner blocks: made of 1/4" fir plywood. These are the mechanical fasteners that hold the frame together. Cornerblocks are generally right triangles 10"x10". The surface grain should be across the joint at perpendicular or diagonal, NOT parallel to it.

Keystones are either rectangular or "keystone" shaped. The keystone shape is slightly stronger but takes longer to make. The keystone would be about 3 1/2"x7"x2 1/2". The rectangular strap would be about 2 1/2 to 3"x7".

Cornerblocks and keystones are secured using an 11 nail/screw pattern for cornerblocks, and a seven to 10 nail/screw pattern depending on fastener and usage.

Once the standard fastener was the clout nail, a soft iron nail that clinched itself when nailed into a metal plate. Now standard fasteners are either pneumatic staples and glue, or since the advent of battery drills, 3/4" screws. Screws are quick and allow easy disassembly. Staples by themselves are not strong enough, but with glue are very fast and permanent.

Once the frame is built, it is covered with muslin or canvas. The canvas is layed on the frame smoothly but not tightly. It is then stapled to the frame along the inside edge about every 6-8". The fabric flaps are folded back and a slightly thinned layer of white glue is painted on the frame. Fold the flaps back and go over it with a wet sponge or paintbrush.

After the glue is dry, trim the excess and size the flat with size water or a coat of paint to tighten the cover.

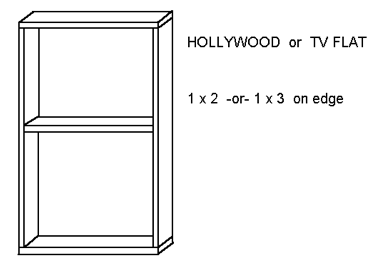

The frame boards are set on edge rather than flat, and may be made of 1x stock, or occasionally of 5/4 stock for rough duty. 1x3 and 1x4 is common, but 1x2 is generally sufficient if of good quality, and helps reduce the weight of the units, as well as significantly reducing required storage space. Instead of canvas, the frame is covered with 1/8" or 1/4" plywood, usually luaun. Luaun is much weaker than fir, but it is lighter and the surface is much smoother.

Construction is simpler than a Broadway flat. The frame is simply nailed together like a box, and the surface nailed, stapled or screwed on. It doesn't need cornerblocks, as the cover will stabilize it.

Each style has its advantages and disadvantages.

Broadway flats, when covered with canvas, are much lighter than a similar size Hollywood. One person can handle a flat. They are also somewhat cheaper in materials too, as canvas is cheaper per square foot that plywood. Canvas also gives a very good painting surface without obvious grain to fight. Since they only take about an inch to store, you can store a number in a fairly thin space. Broadway flats are easy to assemble into corners, as they can be nailed, screwed or lashed.

Hollywoods are easier to get square, somewhat easier to build, and don't flop in the breeze. They are easy to join together, can be clamped or screw together. They are easy to paint, as you can use as roller instead of a brush.

The other technique for flat construction uses structural metal tubing, usually 1"x1" welded into metal frames, basically substituting metal for wood in standard flat construction. Steel is heavier but easier to work with. Aluminum is lighter, but needs inert gas welding for fabrication. Metal frame flats may be fabric covered, with muslin or other covering fastened to thin plywood strips glued and screwed to the frame, or may be hard covered with plywood like hollywood flats. Metal flats are far more durable than wood flats, take less room to store than hollywoods, but are more difficult to construct, requiring an entirely different set of skills and tools.