There are a number of types of wood joints. Some lend themselves to theatre use, some do not.

Boards have Faces (the wide side), Edges and Ends. Joints can be made on all these surfaces, but the joints are not all equal. The strength of a joint will depend on the surface area of the joint. Faces have more surface than edges, and are therefore stronger; edges likewise have more surface than ends.

By far the most common in theatre construction are butt joints and lap joints.

Butt joint: formed when a square cut end is placed against the side of another board. Used for constructing most scenery, and are held together with fasteners and gusset plates.

In theatre, the gussets are corner blocks and keystones.

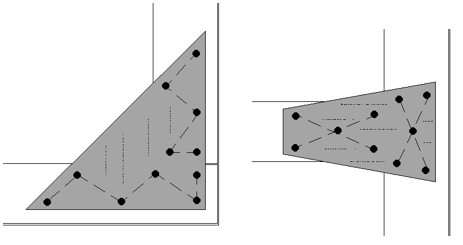

11 nail pattern- used for corner blocks.

10 nail pattern: used for keystones.

Lap Joints when two boards overlap.

The strength of lap joints depends on how much of the joint actually overlaps.

Face to face by definition

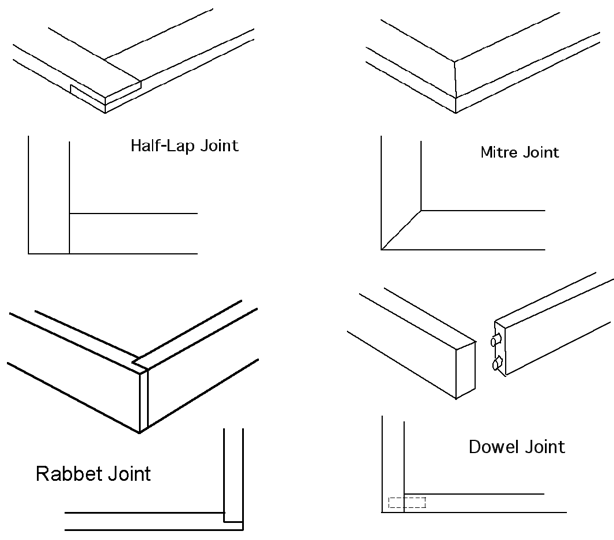

Half laps: half of each board is cut away before lapping.

Has most of the strength of the lap joint, but makes a finished joint only as thick as the stock.

Miter joint: made when two complimentary angles are joined. For 90 degree angles, the complimentary angles are 45 degrees.

Scarf joints: are complimentary tapered like two wedges fitted together; when jointed it creates a board similar to a whole board.

Dado and rabbet joints are similar. A groove is cut into a board face forms a dado. A groove cut on the edge forms a rabbet. They are strong, but rather putzy to make, and so are used mostly to build shelves, etc. that need the strength.

Mortise and tenon joint: strongest of all shop made joints. A socket is cut in one side, and a tongue to fit it in the other. Somewhat tedious and time-consuming to construct, but very strong and stable. It used to be used for toggle rail shoes on flats, but those have been mostly replaced by cornerblocks and keystones.

Dowel joints: simpler replacement for mortise and tenon. Not as strong but are much easier to make. They are commonly used for building furniture.

Variation is the Spline Joint: Uses a strip of wood glued into grooves cut in both boards

Splines are a good way to reinforce miter joints

Another variation is the Biscuit joint: which use wooden wafers instead of dowels.

Dovetail joint: a joint usually found only in very fine cabinetry or furniture. Perhaps the strongest wood joint available, as the wood is locked into place without depending only on mechanical fasteners or glue. Rarely worth the bother of making in theatre, but might be useful where high strength is needed. A prime example is when building drawers in a permanent prop.